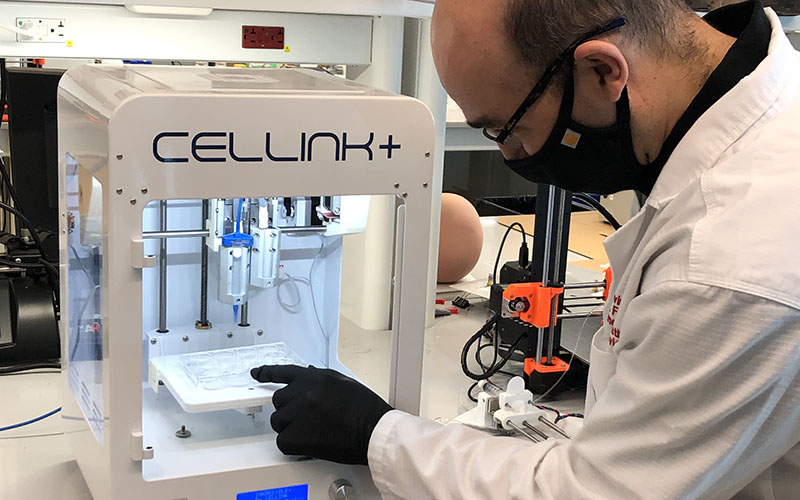

Kevin Aroom, M.S., P.E., is a biomedical engineer with over 12 years of experience as a Senior Engineer in the Department of Surgery and Pediatric Surgery at the University of Texas Health Center in Houston. There, he provided engineering expertise in areas of trauma, resuscitation, and tissue engineering and developed many prototypes for a variety of systems. His areas of research interests include 3D-printing and rapid prototyping, biomedical instrumentation, and medical devices for austere or low-resource environments.

Kevin Aroom, M.S., P.E., is a biomedical engineer with over 12 years of experience as a Senior Engineer in the Department of Surgery and Pediatric Surgery at the University of Texas Health Center in Houston. There, he provided engineering expertise in areas of trauma, resuscitation, and tissue engineering and developed many prototypes for a variety of systems. His areas of research interests include 3D-printing and rapid prototyping, biomedical instrumentation, and medical devices for austere or low-resource environments.

The Fischell Foundry centers on our core staff who bring expertise in prototype development and commercialization.

Connect with usLearn more Let's collaborate | JumpSTART ProgramThe Fischell Foundry is the driving force behind the Fischell Institute's mission to support device innovators throughout the entire commercialization pipeline. Device creation requires coordination, intellectual capital, resources, facilities, and creative individuals who have an intense desire to learn and succeed. We are dedicated to catalyzing the transformation of basic research into clinical practice and commercial success.

Kevin Aroom, M.S., PE

John Rzasa, Ph.D.

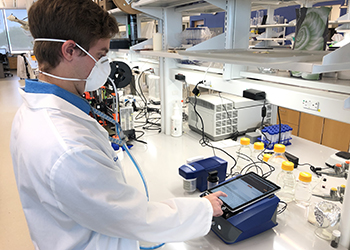

John Rzasa, Ph.D., is an electrical engineer, specializing in laser and electro-optical system design and fabrication, mixed signal circuit design, custom data acquisition systems, and graphical user interfaces to control and gather data. His medical device inventions include a pulse magnetic system for pain treatment, a “smart” otoscope, and a novel measurement system for simultaneously characterizing the electrical and optical properties of chemical and biological materials. He has also developed an electronic home plate capable of differentiating between balls and strikes.

John Rzasa, Ph.D., is an electrical engineer, specializing in laser and electro-optical system design and fabrication, mixed signal circuit design, custom data acquisition systems, and graphical user interfaces to control and gather data. His medical device inventions include a pulse magnetic system for pain treatment, a “smart” otoscope, and a novel measurement system for simultaneously characterizing the electrical and optical properties of chemical and biological materials. He has also developed an electronic home plate capable of differentiating between balls and strikes.

Martha Wang, Ph.D.

Martha Wang, Ph.D., has more than 15 years of experience in biotech ranging from human tissue and cellular-based products to traditional medical devices. She is the Fischell Institute's resident expert in biocompatibility testing, quality assurance requirements, device manufacturing, and post-commercialization. Wang earned her Ph.D. from the Fischell Department of Bioengineering in 2014.

Martha Wang, Ph.D., has more than 15 years of experience in biotech ranging from human tissue and cellular-based products to traditional medical devices. She is the Fischell Institute's resident expert in biocompatibility testing, quality assurance requirements, device manufacturing, and post-commercialization. Wang earned her Ph.D. from the Fischell Department of Bioengineering in 2014.

Ryan Smith

Ryan Smith graduated with his M.S. in mechanical engineering from UMD in 2018. He works closely with doctors and clinicians from the University of Maryland Medical Center and Medical System to build and test medical device prototypes. His work includes a 3D printed breast cancer treatment phantom, a bone screw for SI fusion, and a rapid arterial access device. His areas of interest include additive manufacturing, CNC machining, and Engineering Education.

Ryan Smith graduated with his M.S. in mechanical engineering from UMD in 2018. He works closely with doctors and clinicians from the University of Maryland Medical Center and Medical System to build and test medical device prototypes. His work includes a 3D printed breast cancer treatment phantom, a bone screw for SI fusion, and a rapid arterial access device. His areas of interest include additive manufacturing, CNC machining, and Engineering Education.

Quinn Burke, M. Eng.

Quinn Burke, M. Eng., has been with the Fischell Institute since 2019 when he was an undergrad working with Dr. Lex Schultheis on evaluating the biocompatibility of 3D printed dental resins. After his graduation in 2020, Quinn pursued his M. Eng. in bioengineering as a part of the Fischell Institute's MPower fellowship program. There, he worked to develop a low-cost method for conducting respirator and mask testing. After completing his M. Eng. in bioengineering, Quinn joined the Fischell Institute Foundry as an engineer. He is passionate about medical device development.

Quinn Burke, M. Eng., has been with the Fischell Institute since 2019 when he was an undergrad working with Dr. Lex Schultheis on evaluating the biocompatibility of 3D printed dental resins. After his graduation in 2020, Quinn pursued his M. Eng. in bioengineering as a part of the Fischell Institute's MPower fellowship program. There, he worked to develop a low-cost method for conducting respirator and mask testing. After completing his M. Eng. in bioengineering, Quinn joined the Fischell Institute Foundry as an engineer. He is passionate about medical device development.

Foundry Services

- Desgin, Validation and Verification

- Device Protoyping

- Device Protoype Validation and Verifcation

- Data/Device Development Plan

- Regulatory Pathway Assessment

- Connections with testing facilites and CROs

- FDA Submission Support

- Clinical Trial Desgin

- Intellectual Property and Venture Creation

- U.S. Market Entry for International Companies

Device development assistance includes prototyping, printed circuit board (PCB) construction, fabrication, 3D printing, optical/electrical sensor design, confocal microscopy, small animal imaging, technology validation testing, and many other analytical technologies.

JumpSTART Program

Interested in collaborating? Have an idea but don't know where to start?

Our JumpSTART Program offers:

1. Identify areas of collaboration

2. Fischell Foundry consultation

3. Design and fabricate prototypes

4. Identify follow-on funding

Please submit your project information via this form and the Fischell Foundry will be in touch. Please note you must be affliated with the Fischell Institute to take advantage of this program.

Learn more about the Fischell Foundry

Top