News Story

Fischell Institute Engineers Build Custom Automated System to Advance Electrode Research at UMD

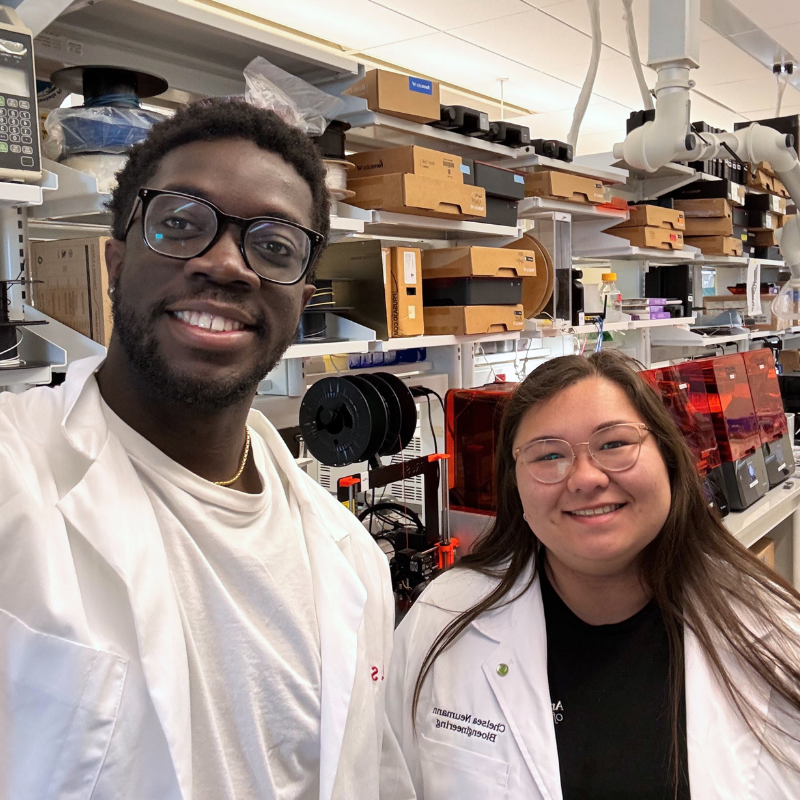

Robert E. Fischell Institute for Biomedical Devices Foundry Senior Engineer Kevin Aroom and Engineer Ryan Smith collaborated with Po-Yen Chen, an assistant professor in the Department of Chemical and Biomolecular Engineering, to design and build an automated system that streamlines electrode pair measurements.

“Working with the Foundry team was like watching a long-term vision come to life,” said Chen. “Aroom and Smith translated our idea of automation in the wet lab into a tangible, working system.”

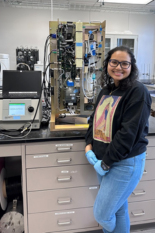

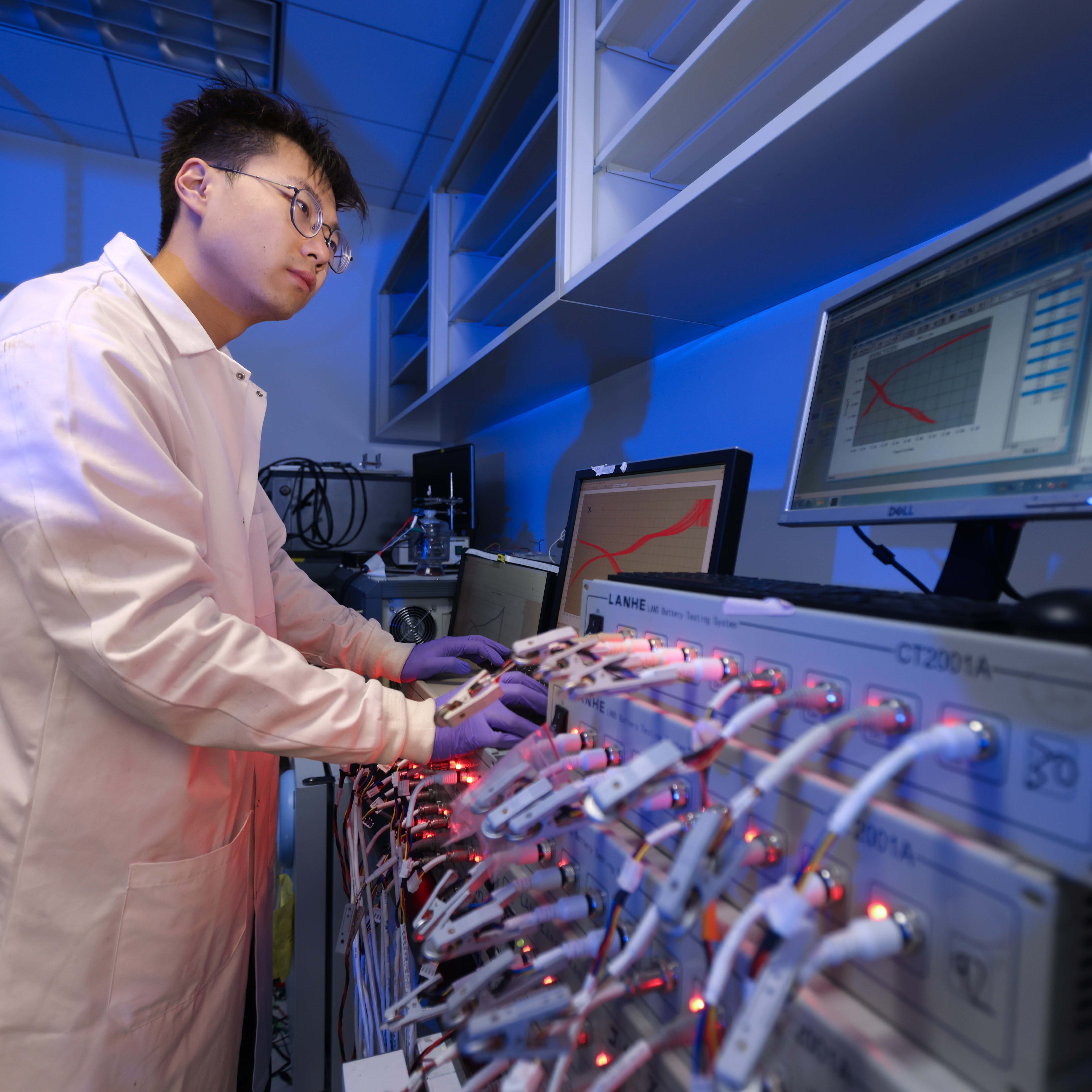

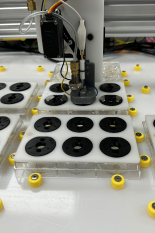

What was once a manual and time-consuming task is now fully automated. The system sequentially selects electrode pairs, transports them to a measurement station, performs readings, ejects them, and repeats the cycle. Aroom and Smith designed the mechanical components, custom parts, and software, creating a cohesive, high-efficiency solution that streamlines experimentation across Chen's Machine Intelligence Accelerated Materials Innovation (MIAMI) Laboratory.

“One of the toughest challenges was designing a mechanism that could reliably pick up, position, and drop off the electrodes,” said Aroom. “We also had to source the right components to ensure a stable electrical connection between the moving assembly and the electrode cartridge. On top of that, creating consistent signal interfaces between the motion control system and other devices was key to making sure the measurements ran smoothly.”

To begin, Aroom and Smith worked with Chen’s lab members to compile a list of project requirements, distinguishing between essential features and desirable additions. From there, the pair selected a CNC motion control system as the project’s foundation and built out custom subsystems tailored to the lab’s needs, including specialized actuators and mechanisms for electrode manipulation. They also developed custom software to control the motion system and coordinate with measurement equipment.

“I’m most proud of leveraging an off-the-shelf CNC motion control system and using its input/output capabilities to interface with other lab equipment,” said Aroom.

Automation is increasingly valuable for scaling experiments, whether to explore a greater range of conditions or boost sample size, according to Aroom.

“Often, students or lab technicians are required to carry out simple tasks at inconvenient times throughout the day,” he said. “Automation helps solve that problem. While generic platforms exist for tasks like pipetting or microscopy, certain research demands more customized mechanical or control solutions.”

By implementing a robotic platform, Chen’s lab is able to ensure that all measurements are conducted under uniform conditions, minimizing inconsistencies and improving both the efficiency of experiments and reliability of data collected.

The Fischell Foundry provides the infrastructure, resources, and support to help transform early-stage research into real-world clinical solutions and successful commercial products.

Published June 20, 2025