News Story

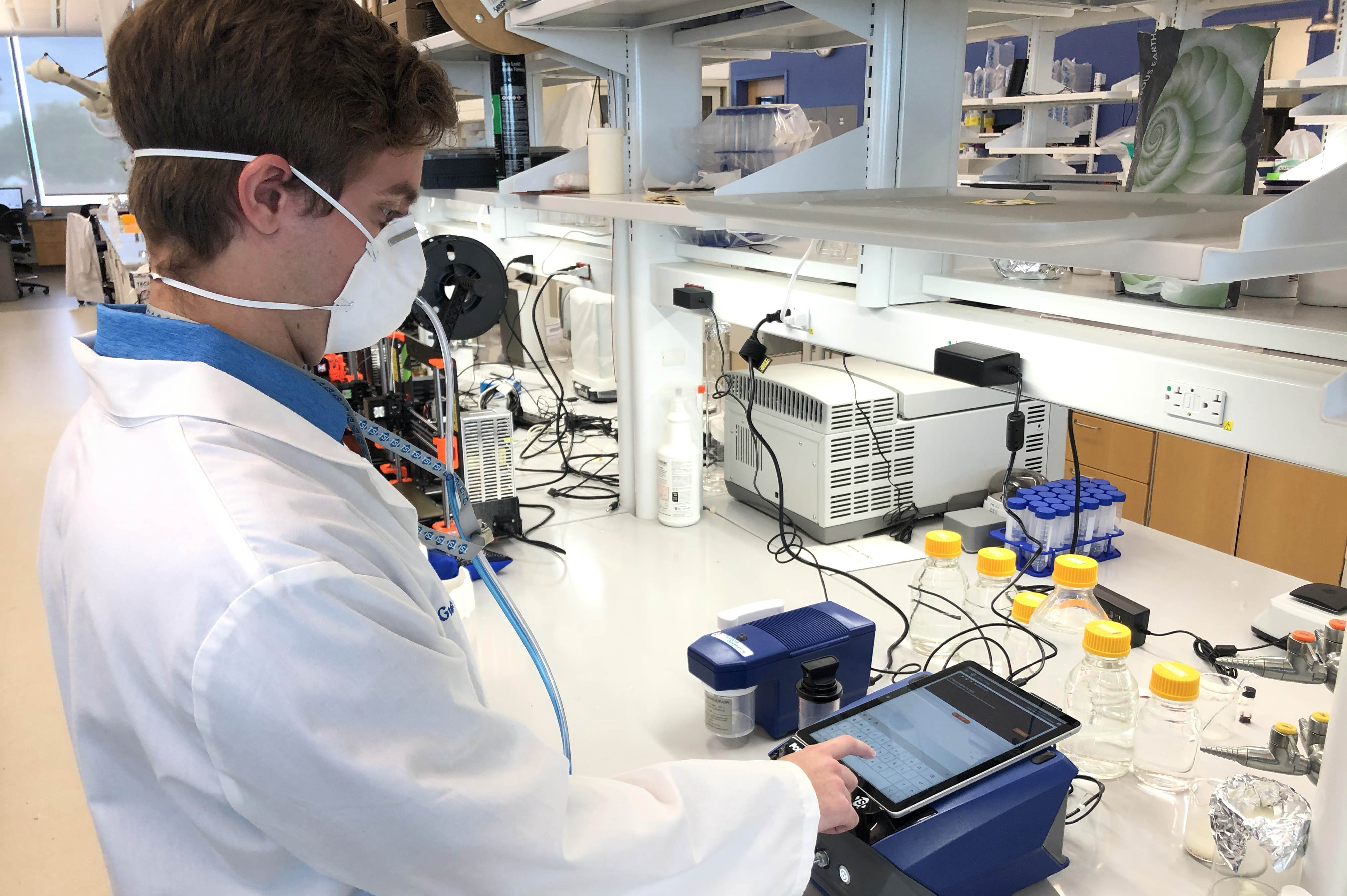

Fischell Foundry Spotlight: Quinn Burke

Robert E. Fischell Institute for Biomedical Devices faculty specialist and engineer Quinn Burke (B.S.'20, M. Eng.‘22 bioengineering) first got involved with the Fischell Institute as an undergraduate working with Fischell Foundry member Lex Schultheis on a dental device project for which Burke conducted DART mass spectrometry analysis on 3D-printed dental devices that were printed using a dental resin and stereolithography (SLA). After printing, the devices were subject to different curing and biocompatibility procedures. The main objective of this work was to explore whether DART mass spectrometry could serve as a useful tool in determining the biocompatibility of these devices.

Burke earned his bachelor's degree in bioengineering and minor in technology entrepreneurship in 2020. After graduation, he decided to further his education with a focus on medical device development so he applied for the Fischell Institute’s MPowering the State Student Entrepreneurship Fellowship, coinciding with the University of Maryland’s M.Eng. in Bioengineering program.

As an M.Eng. student during the height of the COVID-19 pandemic, Burke decided to work on a project focused on respirator mask filtration and regulatory testing with Fischell Foundry engineer Kevin Aroom.

During this time, Burke worked to scale up respirator testing capabilities and primarily focused on developing a low-cost respirator evaluation mechanism. This device aims to serve as a first-pass testing method and could be particularly useful in the development of innovative masks or the testing of alternative materials for masks.

Aside from his respirator testing work, Burke has specialized in the device design process, CAD, CAM for CNC machining, 3D printing, regulatory testing and procedures, data analysis, and Arduino programming. He is currently working on a project focused on mediated electrochemical probing and is developing bioelectronic sensor devices for antibody detection. Using resin-based 3D printing, Burke has worked to optimize the design of these microfluidic devices. With this project, he works with Fischell Institute Director William Bentley and members of Bentley’s lab, Chen-Yu Chen and Dana Motabar.

Outside of engineering, Burke enjoys hiking and spending time outdoors. He is a National Parks enthusiast and hopes to visit as many parks as possible. He is also a huge sports fan and enjoys playing soccer and basketball and going to UMD games.

Published November 17, 2022