News Story

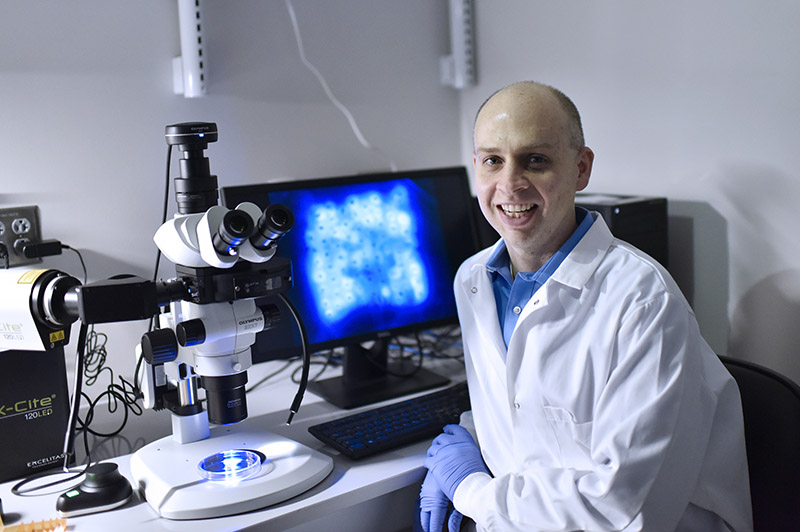

MPowering the State Fellows Develop Novel Shoulder Implant

Tejsavi Subramanya (left) and Rayan Alabsi (right)

Robert E. Fischell Institute for Biomedical Devices 2019 MPowering the State Student Entrepreneurship Fellows Rayan Alabsi and Tejasvi Subramanya have developed the prototype for a novel reverse shoulder implant they hope could change the way shoulder surgeries are done.

Alabsi moved from Saudi Arabia to the United States after completing high school. Then, he earned his undergraduate degree in biomedical engineering with an instrumentation, signals, and imaging specialization from the University of Akron. Subramanya earned his undergraduate degree in mechanical engineering from the National Institute of Engineering in India, where he grew up. Both began their graduate careers in the Master of Engineering (M.Eng.) in Bioengineering program at the University of Maryland last year.

The pair’s prosthesis is designed for patients undergoing Reverse Total Shoulder Arthroplasty (RTSA), the surgical reconstruction and replacement of the shoulder. The damaged shoulder joint is replaced with a prosthesis, with the anatomical ball and socket joint reversed. RTSA is a relatively new surgery; it was approved by the U.S. Food and Drug Administration (FDA) in 2003.

Alabsi and Subramanya were inspired to design a RTSA-specific device because of the rising number of people undergoing the surgery every year. Despite the increase in patients, numerous challenges in prosthesis design, biomechanics positioning, and surgical techniques are still associated with the surgery. Alabsi and Subramanya's device consists of mechanical features which allow for a larger range of motion and significantly smaller risk of joint dislocation and reduction of scapular bone impingement compared with other devices.

“This project is exciting to me because the shoulder is one of the most complicated joints in the body, and is highly vulnerable to injuries. This makes our project challenging and particularly interesting,” Subramanya says.

The pair initially conceived the idea for a novel shoulder implant while taking a biomedical device development course taught by Fischell Department of Bioengineering and Fischell Institute faculty member Martha Wang. At the conclusion of the course, the students submitted a documented design report for the device, and began to think about next steps.

“The process of understanding the designing of the implant gave [us] hopes of bringing it to market,” Subramanya explains. “However, to manufacture prototypes and conduct performance tests, we needed a dedicated technological support. The MPowering the State Student Entrepreneurship Fellowship was the perfect opportunity for us to utilize the required resources and work with the Fischell Institute and bridge our skills with the industry.”

The MPowering the State Student Entrepreneurship Fellowship is a one- to two-year fellowship that helps transition innovative medical device projects into great business ideas by utilizing various programs offered through the University of Maryland, including the M.Eng. in Bioengineering program. Initial application materials for the fellowship include a business plan that maps key elements of the development of their medical device – for example, unmet clinical needs, engineering solutions and specifications, and research of the market and FDA regulatory pathway.

Since July 2019, the fellowship has provided Alabsi and Subramanya with a stipend, access to dedicated lab space and material support for prototype development, and connections with industry and regulatory professionals. Additionally, they work with Fischell Institute researchers – including Wang, engineer Kevin Aroom and faculty member Dr. Lex Schultheis.

“It’s continuous iteration of making the prototypes, then figuring out ways we can enhance it," Alabsi says. "It’s all about overcoming issues with each iteration, and making the device safe and effective, with the ultimate goal of improving the life of the patient. The fellowship has given us the financial support, guidance, and workspace that we need to visualize – and work towards – getting our product on the market. Working on the device on campus where we also take classes is convenient, too.”

Part of Alabsi and Subramanya’s device development research includes attending RTSA operations performed by local surgeons. The two have observed hours of arthroplasty operations and applied the takeaways toward developing new versions of the prosthesis.

“We always need to take that extra step,” Alabsi says of their research. “Absorb as much as you can; watch and learn from industry experts. We’re constantly taking extra steps – and it will all end with our completed project. Above all, we make sure to keep an entrepreneurial mindset.”

Alabsi and Subramanya have disclosed their invention with University of Maryland’s Office of Technology Commercialization, and are in the process of filing a patent through the university.

Published October 1, 2019